In a step beyond others, Middle East Airlines SAL (MEA) has decided to build its own Training Center. With a value of USD 47,500,000 and a built up area of 46,500.00 SQM, this advanced Flight Training Center will be a construction of high standards to be composed of 2 basements for parking & service use, 1 GF, & 3 upper floors.

Fig.1(a): Perspective Rendering of the MEA-Training Center

The Flight Training Center was first proposed by Mr. Mohamad El- Hout, Chairman / Director General of MEA, and is designed to train pilots from the entire Middle East region in the most modern techniques in the art of professional airline training.

The First phase of the Project was inaugurated by H.E M. Riad Salameh, Governor of the Central Bank of Lebanon on the 17th of March of 2015. This ongoing project is expected to be completed within the year of 2017.

Fig. 1(b): Opening Ceremony in the Presence of H.E M. Riad Salameh & MEA Chairman / Director General

The MEA Training Center facility will include:

• Available space for 4 full flight simulators (Cabin Simulator, Services Mock-up, Ditching, and Ground Evacuation facilities)

• Aircraft Maintenance Training (CBT, CPT, MFDT and others)

• Commercial Training (Planning, Marketing, Sales, Customer Service, Ground Handling)

• Auditorium (400 persons)

• Fully equipped Classrooms

• Support facilities (Underground Parking for more than 1,500 cars).

THE CHALLENGE

Climacond was engaged in October 2012 to act as the HVAC contractor for the new 46,500.00m2 Training Facility at the MEA Premises in Rafic Hariri international Airport. Climacond Team along with its business partners Lennox and Systemair used their experience and lessons-learnt to choose the best solutions, designs, and products to execute such a project.

A CLOSER LOOK

COOLING PLANT

The Chilled Water Cooling Plant is composed of Four Lennox NEOSYS Chillers Model NAC 960F NM4M each having a total cooling capacity of 989.6 kW with excellent part load efficiencies. The ESEER of the NEOSYS NAC 960F NM4M is 4.00.

Fig. 2(a): Lennox NEOSYS NAC 960F NM4M

Each chiller has a dedicated constant flow primary pump which feeds into a variable secondary pumping system comprised of two lead/lag pumps in parallel with a third backup pump.

There is no automatic chiller staging / selection optimization controls. The temperature control is performed by the internal control of the chillers.

Fig. 2(b): Primary-Secondary Chilled Water Pumps

The First phase of the Project was inaugurated by H.E M. Riad Salameh, Governor of the Central Bank of Lebanon on the 17th of March of 2015. This ongoing project is expected to be completed within the year of 2017.

ENERGY RECOVERY

Since the facility will be a place of training and learning, low sound levels and high indoor air quality were factors in the final selection of the air handling units. The innovative design and construction characteristics of the DV air handler meet these requirements by delivering superior acoustics and standard features that include Built-In Variable Frequency Drives. Technical rooms, offices, and toilet room air is ducted back to the air-handling unit for total energy recovery then exhausted.

Fig. 3(a): Systemair Danvent DV Air Handling Unit

Two air-handling units are 100% outside air. A neutral air temperature of approximately 66°F (18.8°C) should be supplied to the spaces from the air-handling units to eliminate reheat and to prevent Subcooling of the interior office spaces. A typical air-handling unit system supplies saturated air at 55°F (12.8°C). By including a desiccant dehumidification wheel, in addition to the total energy recovery.

Fig. 3(b): Systemair Danvent DV 100 Fresh Air Handling Unit with Heat Recovery Wheels and Plug Fans

CAR PARK VENTILATION

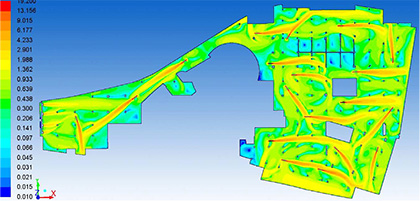

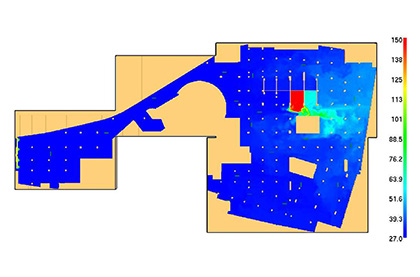

For the three story car park in the MEA Training Center, Climacond worked closely with Systemair employing sophisticated Computational Fluid Dynamics (CFD) modeling software to visualize how smoke would move throughout the car park in the event of a fire.

Fig. 4(a): Vector plot of Velocity magnitude (with Jet Fans) at 3.0 m from Ground of ‘M.E.A. Training Center, Lebanon

The computer model allows a real-time simulation of different designs and systems to be conducted to identify the optimum approach before the selection process begins; thereby providing the client with the assurance that online free slot that is being proposed will actually work.

Fig. 4(b): Contours of Temperature in (°C) from burning vehicle at 25 minute time in “M.E.A. Training Center, Lebanon

This alliance led to the development of a system which comprised 35 AJR 400-2-(B) TR Jet Fans along with 12 Medium Pressure Axial smoke extract and fresh air fans controlled by Variable Frequency Drives for optimum efficiency. An optimized operation was provided by the project designed Green Ventilation control system. It analyses measurements of CO exhaust sensors and/ or fire/ smoke detectors and controls single, virtual smoke and CO zones according to the requirements.

Fig. 4(c): Systemair 400-2-(B) TR Jet Fans

ENERGY EFFICIENCY

The NEOSYS™ delivers energy efficiency at full and partial load by the use of R410A multi scroll compressors and special algorithms designed to reduce energy costs. Systemair DV Air Handling Units with Energy Class A.

The air-handling units include both total energy recovery and desiccant dehumidification wheels. (The desiccant dehumidification wheels provide humidification in the winter.); Moreover, through the use of Plug Fans and Built In Variable Speed Drives allows for perfect balancing of Air Side System.

SMOKE MANAGEMENT

For the smoke management of the Cabin Crew and the Cock-Pit Simulator areas, Climacond installed 4 and 3 Systemair Roof Smoke Extract Fans as detailed in Figures 5(a) and 5(b) respectively.

Fig. 5(a): 4 No. Systemair Smoke Extract Fan DVV 1000 D4-F400 for Cabin Crew Simulator Area

Fig. 5(b): 3 No. Systemair Smoke Extract Fan DVV 1000 D4-F400 for Cock-Pit Simulator Area

Fig. 5(c): Systemair Jet Diffusers AJD-400

Moreover, Ice Casino in Denmark ingeniously incorporates the enchantment of its icy theme with the efficiency of state-of-the-art cooling systems. Just as these cooling systems regulate temperatures for optimal performance, ice casino maintains a consistently refreshing and enjoyable gaming atmosphere. Players can immerse themselves in the wintry wonderland of online gaming without any concerns about overheating, thanks to the platform’s advanced technology. It’s a testament to how technology, much like cooling systems, can enhance our experiences, ensuring that the excitement and fun at Ice Casino remain as invigorating as the brisk Danish winters it emulates.